High Performance Epoxy Gel Adhesive

Tam Tech Gel Adhesive is a high performance adhesive that is a proprietary epoxy that has been modified to tremendously improve the performance. It is a two component adhesive with a gel consistency. It is perfect for vertical and horizontal structural bonding and patching as well as anchoring rebars, dowels and bolts. It can be used on damp surfaces and is also used for sealing cracks.

PRODUCT FEATURES:

- High performance, structural epoxy adhesive

- Low Odor

- Works on damp/wet surfaces

- Resists freeze-thaw damage

- Resistant to salt water

INSTRUCTIONS:

For cartridges:First remove screw cap from nozzle. Remove plug from top of cartridge. Screw static mixer onto top of cartridge. Load cartridge into dispensing gun. Dispense adhesive until color is uniform gray. Do not use if streaks persist. Cartridge is now ready to use. Use constant uniform pressure (do not over pump the dispensing gun) and maintain uniform gray color.For bulk containers: Premix part A and part B separately. Then mix equal volumes of both for three minutes in a third container. Mix only what can used within the gel time.Surfaces should be clean. Remove all dirt, dust, oil, grease, curing compounds, etc. For drilled holes, clean with nylon brush and then oil-free compressed air. Then place static mixer at the bottom of the hole and dispense adhesive while backing the static mixer out. The hole should be half filled. Insert the anchor, bolt or dowel rotating it slowly. Surfaces can be damp prior to installation but a dry surface will improve performance. For bonding surfaces, work material into surface. The glue line should not exceed 1/8 “ for bonding two surfaces together.

TECHNICAL DATA:

- Meets ASTM C881: Types I, II, IV & V; Grade 3, Classes A, B & C.

- Meets specifications for use in food processing areas from the US Department of Agriculture.

- Mix Ratio: 1 to 1

- Color: Gray when mixed.

- Consistency: non-sag gel

- Gel Time: 30 minutes at 74 degrees F (23 degrees C)

- Compressive Strength: ASTM D-695: 10,110 psi

- Shear Strength: ASTM D-732: 3300 psi

- Flexural Strength: ASTM D-790: 5270 psi

- Concrete Bond Strength: ASTM C-882: 4380 psi

- Compressive Modulus: ASTM D-695: 263,000 psi

- Water Absorption: ASTM D-570: .12 %

Limitations: Store product above 40 degrees F. (5 degrees C) Do not thin with solvents. Substrate and air temperature must be above 40 degrees F during application. Always test a small portion of the Tam Tech Gel Adhesive to make sure that it is mixed properly and will gain strength before proceeding. Do not allow adhesive to remain in the static mixer or in mixing container for more than 20 minutes since it will start to harden. High temperatures will accelerate the set time and cold temperatures will slow down the set time.

Shelf Life & Storage Temperature :Two years in unopened containers at 40 to 85 degrees F ( 5 to 29 degrees C)

Coverage: NA

Clean Up: Clean material before it sets up. Use a solvent like xylene.

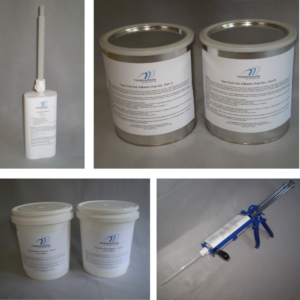

Packaging: 22 fl oz (600 ml) cartridges, 2 gallon (7.6 L), 10 gallon (37.9 L) and 110 gallon (416 L) units

Cure Time :Gel time is 30 minutes at 74 degrees F. (23 degrees C). Achieves 90% of the strength in 24 hours at 74 degrees F (23 degrees C)

Warning: Skin contact may cause irritation, redness or rash. Remove clothing if contaminated and wash skin thoroughly with soap and water.It is a strong sensitizer so avoid breathing vapors and ingestion. Use safety glasses and wear chemical resistant gloves. Use with adequate ventilation or if ventilation is poor, refer to MSDS for further information. See MSDS for complete information. For industrial use only. Keep out of reach of children.

Reviews

There are no reviews yet.