Polypropylene, Polyethylene Structural Adhesive / Glue (cases of 10 cartridges)

Tam Tech Adhesive (50 ml cartridge) is one of the top performing adhesives / glues in the industry. It is a very high performance structural adhesive / glue designed to work with “hard to bond” materials like: HDPE (high density polyethylene), LDPE (low density polyethylene), PE, polypropylene, ABS, nylon, Teflon, rubber, TPE’s (like Santoprene), polycarbonate, fiberglass, PVC and it bonds to concrete, steel and aluminum. It is a modified polymer in a proprietary formulation that requires no primer or special surface preparation and it is supplied in a 1-1 ratio with cartridges.

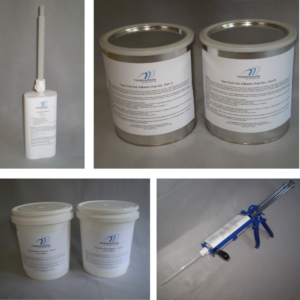

When placing an order, add a Mixing Nozzle (TTA-50MN) required for mixing the adhesive and a Dispensing Gun (DG-50) to dispense the adhesive from the 50 ml cartridge.

Product Features:

- One of top adhesives in the industry (50 ml cartridge)

- Bonds polyethylene & polypropylene

- Bonds dissimilar materials

- Long term structural bond

- No special surface preparation or primer necessary

- Very good chemical resistance

- Excellent resistance to water

- Bonds underwater

- Impact resistant

- Replaces mechanical fasteners

Instructions:

If material to be bonded is smooth (for increased performance but not required) first rough up surface with 120 grit sandpaper or emery cloth. Clean surface from dirt, grease, sanding particles, etc. Then place the 50 ml cartridge in dispensing gun and twist off cap. Pump the gun until both materials comes out. Wipe the end of the cartridge clean. Then attach static nozzle mixer with a twisting motion. Apply uniform pressure and dispense adhesive until color is uniform. (3” to 6” of material) Then apply Tam Tech Adhesive to surfaces to be bonded and attach materials within the 5 – 6 minute working time at 72 degrees F (22 degrees C). Storage: replace cap and store cartridges on their side in the shade or a cool location.

Technical Data:

- VOC Content: Less than 2 %

- Viscosity: Part A 300,000 cP & Part B – 25,000 cP

- Color: Part A – Off White, Part B – Opaque, Mixed – Opaque

- Working time: 5 – 6 minutes at 72 degrees F (22 degrees C)

- Time To Handling Strength: 48 minutes at 72 degrees F (22 degrees C)

- Full cure: 24 – 36 hours

- Shore D Hardness: 60

Tam Tech Adhesive will also bond combinations of the materials listed below in the chart.

| Lap Shear Strength (ISO 4587 / ASTM D3163) lbs/square inch | ||

| Cured Materials | 24 – 36 Hours | |

| HDPE TO HDPE | 2015 | |

| ABS to ABS | 540 | |

| Polypropylene to Polypropylene | 1190 | |

| Polyethylene to Polyethylene | 1040 | |

| Polycarbonate to Polycarbonate | 690 | |

| Teflon to Teflon | 285 | |

| Steel to Polypropylene | 1005 | |

| Steel to HDPE | 1003 | |

| Aluminum to HDPE | 569 | |

| Aluminum to Polypropylene | 560 | |

| Stainless Steel to Polypropylene | 710 | |

| Stainless Steel to HDPE | 705 | |

| PVC to PVC | 695 | |

| EPDM Rubber to EPDM Rubber | 525 | |

| PET to PET | 705 | |

| Carbon Fiber to Carbon Fiber | 1090 | |

| Glass Reinforced Polyester (GRP) to GRP | 1310 | |

Limitations:Store product on it’s side at less than 75 degrees F. (24 degrees C). Substrate and air temperature should be above 40 degrees F (4 degrees C) during application. Cool weather will slow down cure time and warm weather will accelerate it. Always test a small portion of the Tam Tech Adhesive to insure it is mixed properly and will gain strength before proceeding with your application.

Storage & Shelf Life: Store cartridges on their side in the shade or a cool location at 75 degrees F or less. Shelf life can be extended with storage in a refrigerator, but do not freeze.

Packaging: 50 ml (1.7 fl oz) cartridges (cases of 10 cartridges) and 400 ml (13.5 fl oz) cartridges available

Cure Time: Time to handle – 1 hour, Working strength in 7 hours, Full cure in 24 to 36 hours.

Warning: Skin contact may cause irritation, redness or rash. Wash thoroughly with soap and water after handling. Use safety glasses and wear protective gloves. Keep out of eyes, may cause eye damage, rinse with water for several minutes and seek medical attention. Use with adequate ventilation or if ventilation is poor, refer to SDS for further information. See SDS for complete information. For industrial use only. Keep out of reach of children.

Reviews

There are no reviews yet.